Home Page

> Tube-Rod > Induction Hardened Cr. Plated Rods > Induction Hardened Cr. Plated Rods >

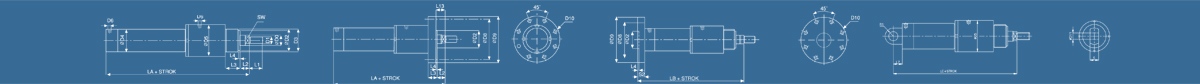

Induction Hardened Cr. Plated Rods

Induction hardened hard chrome plated rods with Ck45 quality, excellent surface roughness, optimum corrosion resistance and high impact resistance for hydraulic-pneumatic cylinders and other applications.

Standart Karşılıkları

ISO Tolerances

Chemical Compositions

Mechanical Properties

According to EN 10083-2.

Corrosion Resistance Properties

The corrosion resistance salt spray test is according to ISO 10289.

Standart Karşılıkları

| EN 10083 | Material No. |

DIN | STAS 500 |

AFNOR A36101 A35501 |

BS 1449 4360 |

UNI 7070 |

JIS G3106 |

GOST 380 19281 |

AISI SAE ASTM |

| C45E | 1.1191 | Ck45 | OLC45X | 2C45 XC42H1 XC45 XC48H1 | 080M46 060A47 | C43 C46 |

S45C S48C |

45 | 1045 |

| Technical Specifications | |

| Steel Grade | C45E (EN 10083) |

| Diameter Range | Ø6 to Ø200 mm |

| Tolerance Class | ISO f7 |

| Roundness | Diameter tolerance / 2 |

| Standard Lengths | For Ø < 60 mm: 5600 - 6200 mm For Ø ≥ 60 mm: 5800 - 7200 mm Upon request: special lengths on all diameters |

| Surface Roughness | Ra max. 0.2 µm |

| Surface Hardness | min 55 HRC |

| Hardened Layer Depth | from 0.5 to 3.5 mm |

| Chrome Layer Thickness | < Ø20 mm: min. 15 µm ≥ Ø20 mm: min. 20 µm |

| Chrome Layer Hardness |

min. 900 HV (0,1) |

| Straightness | ≤ Ø16 mm: max. 0.3 mm : 1000 mm > Ø16 mm: max. 0.2 mm : 1000 mm |

ISO Tolerances

| Ø | > 6 mm ≤ 10 mm |

> 10 mm ≤ 18 mm | > 18 mm ≤ 30 mm | > 30 mm ≤ 50 mm | > 50 mm ≤ 80 mm | > 80 mm ≤ 120 mm |

> 120 mm ≤ 180 mm | > 180 mm ≤ 200 mm |

| f7 | -10 μm -22 μm |

-16 μm -34 μm |

-20 μm -41 μm |

-25 μm -50 μm |

-30 μm -60 μm |

-36 μm -71 μm |

-43 μm -83 μm |

-50 μm -96 μm |

Chemical Compositions

| C | Si max. |

Mn | P max. |

S max. |

Cr max. |

Mo max. |

Ni max. |

V |

| 0.42-0.50 | 0.40 | 0.50-0.80 | 0.035 | 0.035 | 0.4 | 0.1 | 0.4 | - |

Mechanical Properties

According to EN 10083-2.

Corrosion Resistance Properties

| Standard Rods | Upon Request |

| For Ø < 20 mm: Rating 9 after 120 h in NSS | Rating 9 after 500 h in NSS |

| For Ø ≥ 20 mm: Rating 9 after 200 h in NSS |

The corrosion resistance salt spray test is according to ISO 10289.

| Diameter mm |

Weight Kg/m |

Diameter |

Weight Kg/m |

|

| * 6 | 0,22 | 63 | 24,46 | |

| * 8 | 0,39 | * 65 | 26,03 | |

| * 10 | 0,62 | 70 | 30,19 | |

| * 12 | 0,89 | * 75 | 34,66 | |

| * 16 | 1,58 | 80 | 39,44 | |

| * 18 | 2 | * 85 | 44,52 | |

| 20 | 2,46 | 90 | 49,91 | |

| 22 | 2,98 | * 95 | 55,61 | |

| 25 | 3,85 | 100 | 61,62 | |

| 28 | 4,93 | * 110 | 74,56 | |

| 30 | 5,55 | * 120 | 88,73 | |

| 32 | 6,31 | * 125 | 96,28 | |

| 35 | 7,55 | * 130 | 104,14 | |

| 36 | 7,99 | * 140 | 120,78 | |

| * 38 | 8,9 | * 150 | 138,65 | |

| 40 | 9,86 | * 160 | 157,75 | |

| 45 | 12,48 | * 170 | 178,08 | |

| 50 | 15,41 | * 180 | 199,65 | |

| * 55 | 18,64 | * 190 | 222,45 | |

| 56 | 19,32 | * 200 | 246,48 | |

| 60 | 22,18 |

Hardened surface depth

| Ø mm |

6 | 8 | 10 | 12 | 16-18 | 20-22 | 25 | 28 | 30-35 | 40-45 | 50-85 | 90-100 | 110-140 | 150-200 |

| Derinlik mm |

0.5 0.8 |

0.6 0.9 |

0.7 1.0 |

0.8 1.2 |

1.1 1.5 |

1.2 1.5 |

1.5 1.7 |

1.5 1.8 |

1.5 1.9 |

1.6 2.0 |

2.2 2.6 |

2.2 3.2 |

2.4 3.4 |

2.5 3.5 |

* Please contact us for the stock statuses of the dimensions marked with *.

You can contact us for your requests for chrome plated shaft with special diameters not given in the list.