Home Page

> Hydraulic > Telescopic Hydraulic Cylinders > Telescopic Hydraulic Cylinders >

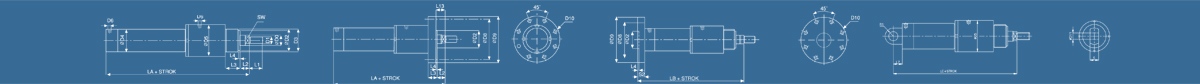

Telescopic Hydraulic Cylinders

Specifications

» Assembly dimensions and mounting types meet MAG standards.

» With single or double-acting versions

» Piston diameter: 65 mm - 180 mm

» Piston rod diameter: 20 mm - 166 mm

» Stroke length up to 5000 mm (optionally, it can be increased)

» With 2, 3, 4 stage options

Technical Specifications

Standards:

Assembly dimensions and mounting types meet MAG standard.

Test standard is ISO 10100.

Nominal Pressure: 160 Bar (16 MPa)

Test Pressure: 240 Bar (24 MPa)

Optionally, it can be manufactured with an operating pressure of 250 bar (25 MPa)

Fluid Type: Mineral oils DIN 51524 HL, HLP.

Fluid Temperature: -20 °C to +80 °C

Operating Temperature: -20 °C to +80 °C.

Viscosity: 5 cSt – 300 cSt

Piston Speed: Maximum 0.5 m/s.

Cleanliness class according to ISO Standard

Maximum permissible pollution level of hydraulic fluid is ISO 4406 (c) class 20/18/15.

Cleanliness classes specified for components in hydraulic system should be provided. Efficient filtering prevents errors and increases the life of components.

Application Conditions:

» Movement axes and connection points of telescopic cylinder and piston rod should be mechanically aligned. Any lateral loads to piston rod and piston bearings should be avoided. Weight of telescopic cylinder or piston rod should be considered.

» Buckling length and buckling load of piston rod and/or telescopic cylinder should be considered.

» Compliance of sealing elements with fluid should be considered at maximum piston speed.

» Maximum operating pressure should be complied at each operation of telescopic cylinder.

» Adverse effects such as aggressive fine particles, vapours, high temperature and compressed air contamination should be avoided.

Materials:

Cylinder tube is manufactured from honed St52Bk+S material. Piston rod is manufactured from St52Bk+S material with a surface plated with minimum 20 µm hard chrome at f7 tolerance.

Test:

Each cylinder is subjected to internal and external leak tightness test in accordance with MAG standards and ISO 10100 standards before being shipped.

Warranty and Service:

MAG telescopic cylinders are under the warranty of our company for 2 years. Also, service and spare part support is provided for 10 years. User induced errors and errors resulting from inappropriate operating conditions are outside the scope of warranty.

Service and repair activities are performed by MAG personnel. In the cases of any damage which may occur during assembly of the product to system and any intervention on product made by persons other than MAG personnel for the purpose of repair and maintenance, the warranty of product is cancelled.

You can contact with us for your requests for any kinds of special design cylinders.