Home Page

> Pneumatic > Air Preparation Units > MFRY Series Air Preparation Units > MFRY 1/2 Series Air Preparation Units >

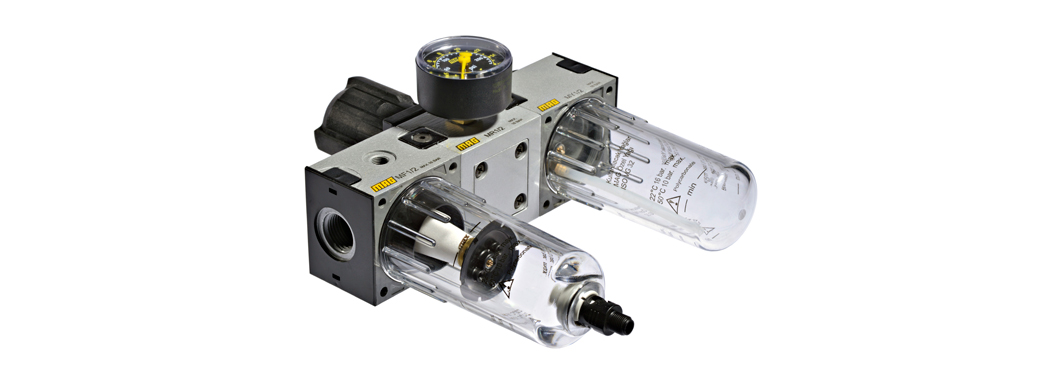

MFRY 1/2 Series Air Preparation Units

Specifications

» G 1/2" or G 3/8" air inlet outlet ports

» Light and compact design

» Easily interconnectable

» High flow rate and efficiency

» Precision pressure adjustment

» Semi-automatic and automatic drain options

» Long life

Technical Specifications

Technical Specifications of MF 1/2" (3/8- B) Filter

Standards: ISO 5782 Filter standard

Operating Pressure: 0 - 16 Bar

Operating Temperature: 0 °C to +50 °C (at 10 bar)

Filtration Value: 30 µm

Flow rate MF 1/2": 1900 L/min

Flow rate MF 3/8"- B: 850 L/min

Efficiency MF 1/2": 98%

Efficiency MF 3/8"- B: 98%

Discharge Method: Semi-automatic; can be automatic discharge upon request

Test: Operating test is applied in compliance with MAG standards and ISO 5782 standard before delivering to each filter.

Technical Specifications of MR 1/2" (3/8- B) Regulator

Standards: ISO 6953 Regulator standard

Inlet Pressure: 0 - 16 Bar

Outlet Pressure: 0.5 - 8 Bar; optionally 0.5 - 4 and 0.5 - 16 bar

Operating Temperature: 0 °C to +60 °C (at 10 bar)

Minimum Pressure Difference: P1 - P2 = 0.2 bar

Flow Rate MR 1/2": 1900 L/min

Flow Rate MR 3/8"- B: 1900 L/min

Test: Operating test is applied in compliance with MAG standards and ISO 6953 standard before delivering to each regulator.

Technical Specifications of MY 1/2" (3/8- B) Lubricator

Standards:

ISO 6301 Lubricator standard

ISO VG 32 Class MAG special air preparation unit lubricator should be used.

Operating Pressure: 0 - 16 Bar

Operating Temperature: -20 °C to +50 °C (at 10 bar)

Air-Oil Mixing Ratio: can be adjusted with adjusting screw

Flow rate MY 1/2": 1900 L/min

Flow rate MY 3/8"- B: 850 L/min

Test: Operating test is applied in compliance with MAG standards and ISO 6301 standard before delivering to each lubricator.

Technical Specifications of MFR 1/2" (3/8- B) Filter + Regulator

Standards:

ISO 6953 Regulator and Filter + Regulator Standard

Inlet Pressure: 0 - 16 Bar

Outlet Pressure: 0.5 - 8 Bar; optionally 0.5 - 4 and 0.5 - 10 bar

Operating Temperature: 0°C to +50 °C (at 10 bar)

Filtration Value: 30 µm

Minimum Pressure Difference: P1 - P2 = 0.2 bar

Flow rate MFR 1/2": 1900 L/min

Flow rate MFR 3/8"-B: 850 L/min

Efficiency MF 1/2": 95%

Efficiency MF 3/8"- B: 96%

Discharge Method: Semi-automatic; can be automatic discharge upon request.

Test: Operating test is applied in compliance with MAG standards and ISO 6953 standard before delivering to each filter + regulator.

Warranty and Service:

MAG MFRY series conditioners are under the warranty of our company for 2 years against manufacturing defects. Also, service and spare part support is provided for 10 years.

Service and repair activities must be performed by MAG personnel. In the cases of any damage which may occur during assembly of the product to system and any intervention on product made by persons other than MAG personnel for the purpose of repair and maintenance, the warranty of product is cancelled.